Custom Smd 5630 Led Chip Red And Green 0.4w Dual Color For Neon Led

Place of Origin: SHENZHEN

Brand Name: Yuhang

Certification: CE.SGS.ROHS

Model Number: YH5630RG04

Delivery Time: 5-7 work days

Payment Terms: T/T, Western Union,Paypal

Supply Ability: 8KK/Days

Detailed Product Description

| Type: | smd led | Chip Material: | InGaN |

|---|---|---|---|

| Emitting Color: | Red/Green | Luminous Intensity: | Customers' Requirements |

| Luminous Flux(lm): | R:5-8LM/G:15-20LM | Power: | 0.4W |

| Viewing Angle(°): | 120 Degree | Color Rendering Index: | Null |

| Color Temperature: | R:620-625NM/G:520-525NM | Operating Temperature: | -20 - 85°C |

| Chip Brand: | Epistar Chip, Sanan Chip,Epileds Chip | Current: | 120mA |

| Voltage: | R:2.0-2.4V/G:3.0-3.4V | Warranty: | 2 Years |

| Lifespan: | 50000-100000H |

Yuhang Special custom smd led 5630 chip Red + Green 0.4w dual color Full spectrum for Neon led

| TYPE | COLOR | CCT(k) | VIEW ANGLE | BRIGHTNESS(mcd) | VF(Typ) |

| 5630 BLUE SMD LED | BLUE | 460-470nm | 120 | 8-12LM | 3.0 |

| 5630 GREEN SMD LED | GREEN | 520-525nm | 120 | 30-40LM | 3.0 |

| 5630 YELLOW SMD LED | YELLOW | 580-595nm | 120 | 10-15LM | 2.0 |

| 5630 RED SMD LED | RED | 620-630nm | 120 | 15-20LM | 2.0 |

| 5630 WARM WHITE SMD LED | WARM WHITE | 3000K | 120 | 50-55LM | 3.0 |

| 5630 WARM WHITE SMD LED | WARM WHITE | 4500K | 120 | 50-55LM | 3.0 |

| 5630 WARM WHITE SMD LED | PURE WHITE | 6000K | 120 | 55-60LM | 3.0 |

| 5630 COOL WHITE SMD LED | COOL WHITE | 10000k | 120 | 50-55LM | 3.0 |

Products Name

5630 0.4W RED+GREEN bicolor led chip

Products Description

Features

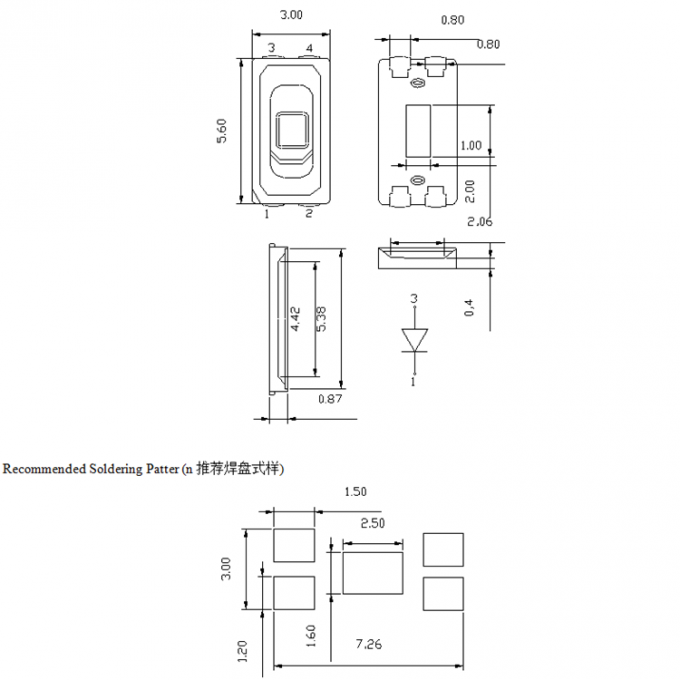

Package ( L/W/H ) : 5.6×3.0×0.87 mm

Color : Ultra High Bright Red+Green

Lens: Water Clear Flat Mold

EIA STD Package

Meet ROHS, Green Product

Compatible With SMT Automatic Equipment

Compatible With Infrared Reflow Solder Process

Package Profile & Soldering PAD Suggested

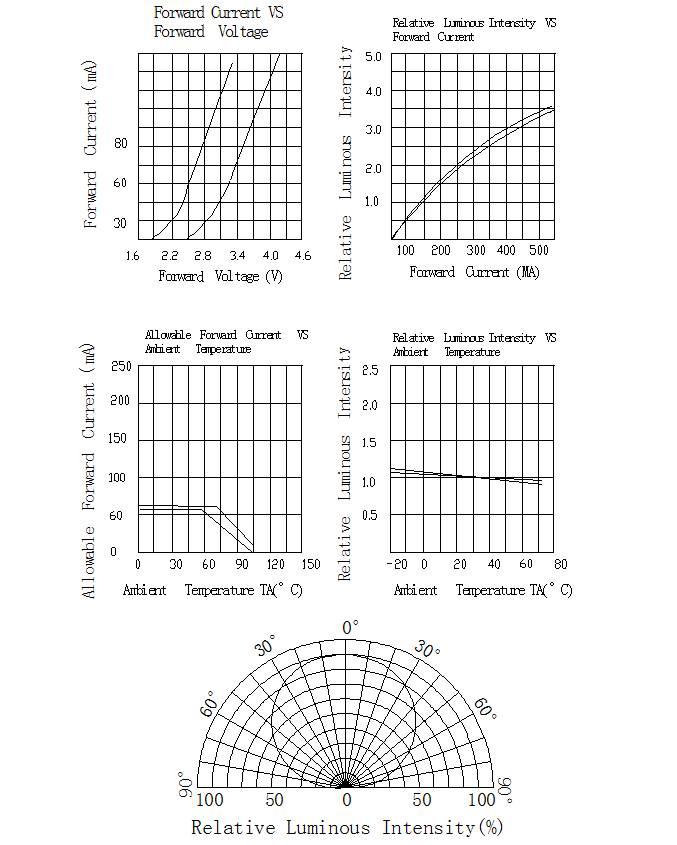

Absolute Maximum Ratings At Ta=25℃

SURFACE MOUNT LED LAMPS Product Type:YHYB5050 Absolute maximum ratings (Ta=25°C) Parameter Symbol Value Unit Forward current If 60 mA Reverse voltage Vr 5 V Power dissipation Pd 0.4 W Operating temperature range Top -25~+80 °C Storage temperature range Tstg -30~+85 °C Peak pulsing current

(1/8 duty f=1KHz)

Ifp 100 mA Electro-Optical characteristics (TA=25°C) Parameter

Test

Condition

Symbol

Color

Value Unit Min Typ Max Color Temperature If=120mA CCT R

G

-- -- -- K Forward voltage If=120mA Vf R

G

2.0

3.0

-- 2.4

3.4

V luminous flux If=120mA φ R

G

5

15

-- 8

20

Lm Viewing angle at 50% IV

If=120mA 2θ1/2 -- -- 120 -- Deg Dominant wavelength

If=120mA λd R

G

620

520

-- 630

525

nm Reverse current Vr=5V Ir -- -- 5 -- μA

Please read the following notes before using the product:

1. Over-current-proof

Customer must apply resistors for protection, otherwise slight voltage shift will cause big current change (Burn out will happen).

2. Storage

2.1 Do not open moisture proof bag before the products are ready to use.

2.2 Before opening the package, the LEDs should be kept at 30℃ or less and 90%RH or less.

2.3 The LEDs should be used within a year.

2.4 After opening the package, the LEDs should be kept at 30℃ or less and 70%RH or less.

2.5 The LEDs should be used within 168 hours (7 days) after opening the package.

2.6 If the moisture adsorbent material (silica gel) has fabled away or the LEDs have exceeded the storage time, baking treatment should be performed using the following conditions. Baking treatment: 60±5℃ for 24 hours.

3. Soldering Condition

3.1 Pb-free solder temperature profile.

3.2 Reflow soldering should not be done more than two times.

3.3 When soldering, do not put stress on the LEDs during heating.

3.4 After soldering, do not warp the circuit board.

4. Soldering Iron

Each terminal is to go to the tip of soldering iron temperature less than 260℃ for 5 seconds within once in less than the soldering iron capacity 25W. Leave two seconds and more intervals, and do soldering of each terminal. Be careful because the damage of the product is often started at the time of the hand solder.

5. Repairing

Repair should not be done after the LEDs have been soldered. When repairing is unavoidable, a double-head soldering iron should be used (as below figure). It should be confirmed beforehand whether the characteristics of the LEDs will or will not be damaged by repairing.

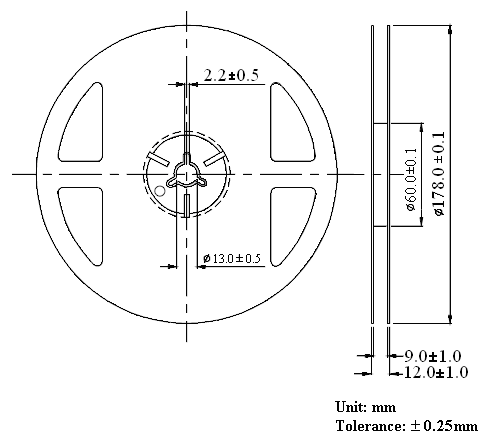

Reel Dimensions:

Carrier Tape Dimensions:

Loaded quantity 3000 PCS Per reel.

INQUIRY

CATEGORIES

CONTACT US

Contact:Vicky

WhatsApp/Wechat:86-13410359515

E-mail:info@smdledlamp.com

Add:5B13-1, Futian Market Building, Fuhua Road, Futian District, Shenzhen