Green Smd Led 2835 1w 60 - 80 LM 520 - 530 Nm , Landscape Led Light Spare Parts

Place of Origin: SHENZHEN

Brand Name: Yuhang

Certification: CE.SGS.ROHS

Model Number: YHG12835

Minimum Order Quantity: 12K

Delivery Time: 5-7 work days

Payment Terms: T/T, Western Union,Paypal

Supply Ability: 8KK/Days

Detailed Product Description

| Type: | smd led | Chip Material: | InGaN |

|---|---|---|---|

| Emitting Color: | Green | Luminous Intensity: | Customers' Requirements |

| Luminous Flux(lm): | 60-80LM | Power: | 1W |

| Viewing Angle(°): | 120 Degree | Color Rendering Index: | Null |

| Color Temperature: | 520-525nm | Operating Temperature: | -20 - 85 |

| Chip Brand: | Epistar Chip , Sanan Chip , Epileds Chip | Current: | 300mA |

| Voltage: | 3.0-3.4V | Warranty: | 2 Years |

| Lifespan: | 50000-100000H |

High lumen 1w 60-80LM Green 520-530nm 2835 smd package led for landscape lighting

Yuhang 3030 SMD LED covers a very full range of wavelength. Yuhang 3030 SMD

LED has stable quality because of its high thermal conductivity and high light transmittance in packaging structure. In the optical design, it solves the application of optoelectronic products for more customers. It owns core technology in raw material collocation, tested by high temperature and humidity, hot and cold impact, high temperature aging and other reliability tests. The product has a very good compatibility,operability. It has a high advantage over the application for stage lighting, outdoor lighting, landscape lighting, etc.Features:

·high cost performance

·red copper base structure with high heat conductivity

.120° Beam Angle

·RoHS, LM-80 certified

·>50000Hrs

.Excellent color consistency

·Reflow soldering available

| Part No. | Chip Material | Lens Color | Source Color |

| YHG12835 | AlGaInP | Water Clear | Green |

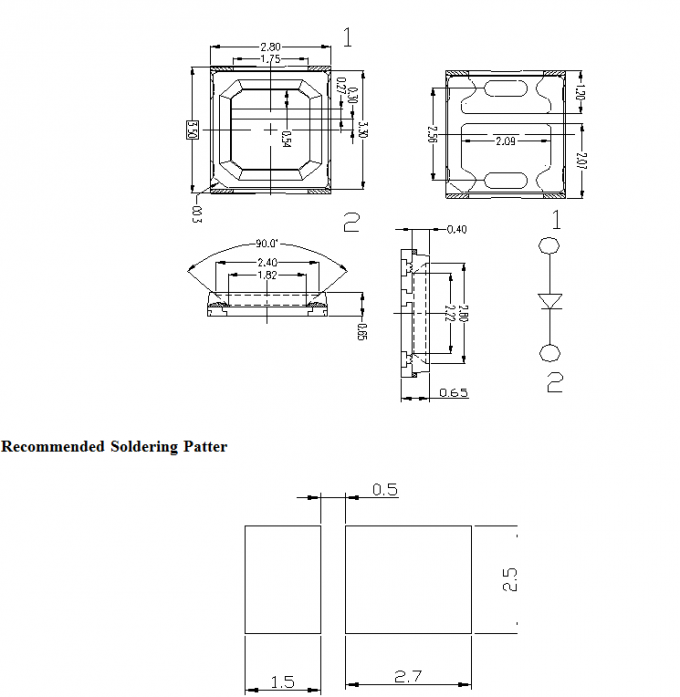

Package Dimensions

| Power | Color | CCT/ Wavelength | Voltage | Current | Lumen | Chip Brand & Size |

| 1W | Red | 620-630nm | 2.0-2.6V | 300mA | 30-40LM | Epileds 30mil |

| 1W | Deep Red | 650-660nm | 2.0-2.6V | 300mA | 15-25LM | Epileds 30mil |

| 1W | Green | 520-530nm | 2.8-3.4V | 300mA | 60-80LM | Epileds 28mil |

| 1W | Amber | 600-610nm | 2.0-2.6V | 300mA | 30-40LM | Epileds 42mil |

| 1W | Yellow | 585-595nm | 2.0-2.6V | 300mA | 30-40LM | Epileds 40mil |

| 1W | Blue | 460-470nm | 2.8-3.4V | 300mA | 25-30LM | Epileds 30mil |

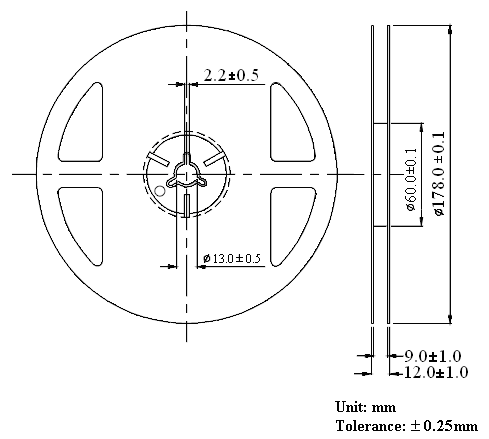

Reel Dimensions:

Carrier Tape Dimensions:

Loaded quantity 4000 PCS Per reel.

Please read the following notes before using the product:

1. Over-current-proof

Customer must apply resistors for protection, otherwise slight voltage shift will cause big current change (Burn out will happen).

2. Storage

2.1 Do not open moisture proof bag before the products are ready to use.

2.2 Before opening the package, the LEDs should be kept at 30℃ or less and 90%RH or less.

2.3 The LEDs should be used within a year.

2.4 After opening the package, the LEDs should be kept at 30℃ or less and 70%RH or less.

2.5 The LEDs should be used within 168 hours (7 days) after opening the package.

2.6 If the moisture adsorbent material (silica gel) has fabled away or the LEDs have exceeded the storage time, baking treatment should be performed using the following conditions. Baking treatment: 60±5℃ for 24 hours.

3. Soldering Condition

3.1 Pb-free solder temperature profile.

3.2 Reflow soldering should not be done more than two times.

3.3 When soldering, do not put stress on the LEDs during heating.

3.4 After soldering, do not warp the circuit board.

4. Soldering Iron

Each terminal is to go to the tip of soldering iron temperature less than 260℃ for 5 seconds within once in less than the soldering iron capacity 25W. Leave two seconds and more intervals, and do soldering of each terminal. Be careful because the damage of the product is often started at the time of the hand solder.

5. Repairing

Repair should not be done after the LEDs have been soldered. When repairing is unavoidable, a double-head soldering iron should be used (as below figure). It should be confirmed beforehand whether the characteristics of the LEDs will or will not be damaged by repairing.

6. Caution in ESD

Static Electricity and surge damages the LED. It is recommended to use a wrist band or anti-electrostatic glove when handling the LED. All devices, equipment and machinery must be properly grounded.

INQUIRY

CATEGORIES

CONTACT US

Contact:Vicky

WhatsApp/Wechat:86-13410359515

E-mail:info@smdledlamp.com

Add:5B13-1, Futian Market Building, Fuhua Road, Futian District, Shenzhen