Cool White 3014 SMD LED White 3.0 - 3.4 V 50000 - 100000 H Lifespan

Product Details:

Place of Origin: SHENZHEN

Brand Name: Yuhang

Certification: CE.SGS.ROHS

Model Number: YH3014W

Delivery Time: 5-7 work days

Payment Terms: T/T, Western Union,Paypal

Supply Ability: 8KK/Days

Detailed Product Description

| Type: | smd led | Chip Material: | InGaN |

|---|---|---|---|

| Emitting Color: | Pure White | Luminous Intensity: | Customers' Requirements |

| Luminous Flux(lm): | 10-14LM | Power: | 0.1W |

| Viewing Angle(°): | 120 Degree | Color Rendering Index: | 80 |

| Color Temperature: | 6000-6500K | Operating Temperature: | -20 - 85 |

| Chip Brand: | Epistar Chip, Sanan Chip,Epileds Chip | Current: | 30mA |

| Voltage: | 3.0-3.4V | Warranty: | 2 Years |

| Lifespan: | 50000-100000H |

Shenzhen Manufacturer Datasheet LM80 0.1W 3014 SMD LED high brightness white cool white chip

Specification

|

Product Information |

|

|

item name |

0.1W 3014 SMD LED |

|

Power |

0.1W |

|

voltage |

2.9-3.3V |

|

Current |

30ma |

|

CRI |

80 |

|

Life span |

50000hours |

|

Warranty |

2 years |

|

Beam angle |

120degree |

|

color

|

luminous flux |

CCT(K) |

CRI |

voltage |

|

warm white |

10-12lm |

2800-3300 |

80 |

2.9-3.1V |

|

natural white |

4000-4500 |

2.9-3.1V |

||

|

daylight white |

5000-5500 6000-6500

|

2.9-3.1V |

||

|

cool white |

>7000K |

2.9-3.1V |

Product Description

Product features:

1.High Lumens Output & Low Brightness Decay

2.Stable Performance & Great CCT Inity.

3.Wid Color Temperature Range

4.High CRI More Than 80

Product quality:

1. First-Choice for Indoor Ligting

2.good raw materials

3. Copper layer

4. Gold wire connection

5.San'an chips

6. Lifespan is >50 000 hours easily

| SURFACE MOUNT LED LAMPS | ||||||||||

| Product Type:YHW3014 | ||||||||||

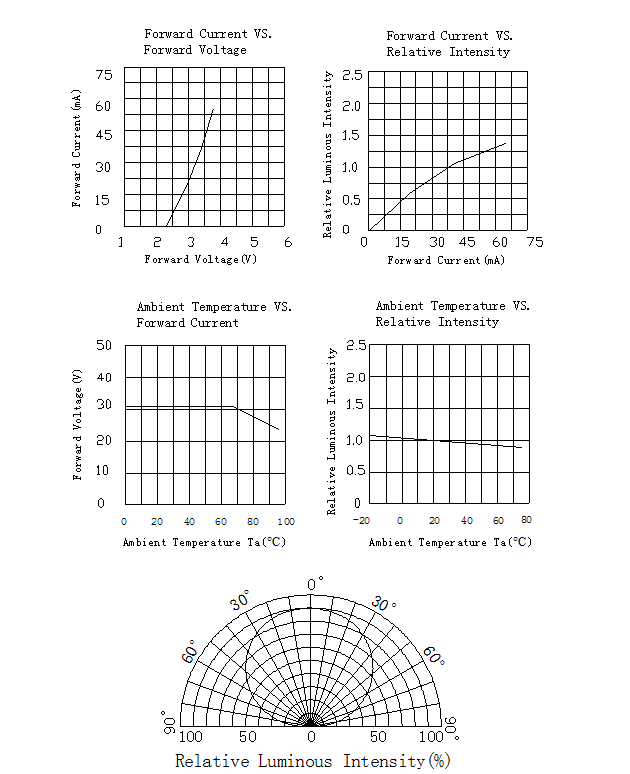

| Absolute maximum ratings (Ta=25°C) | ||||||||||

| Parameter |

Symbol |

Value | Unit | |||||||

| Forward current |

If |

30 | mA | |||||||

| Reverse voltage | Vr | 5 | V | |||||||

| Power dissipation | Pd | 100 | MW | |||||||

| Operating temperature range | Top | -25~+80 | °C | |||||||

| Storage temperature range | Tstg | -30~+85 | °C | |||||||

| Peak pulsing current(1/8 duty f=1KHz) | Ifp | 50 | mA | |||||||

| Junction Temperature | Tj | 115 | ℃/W | |||||||

| Electrostatic Discharge(HBM) | ESD | 1000 | V | |||||||

| Electro-Optical characteristics (TA=25°C) | ||||||||||

|

Parameter |

Test Condition |

Symbol |

Color |

Value | Unit | |||||

| Min | Typ | Max | ||||||||

|

Color Temperature |

IF=30mA | CCT | W | 6000 | -- | 6500 | K | |||

|

Forward voltage |

IF=30mA | Vf | W | 3.0 | -- | 3.6 | V | |||

|

luminous flux |

IF=30mA | φ | W | 10 | -- | 14 | LM | |||

|

Viewing angle at 50% IV |

IF=30mA | 2θ1/2 | W | -- | 120 | -- | Deg | |||

|

Dominant wavelength |

IF=30mA | λd | -- | -- | -- | -- | nm | |||

|

Reverse current |

Vr=5V | Ir | W | -- | 5 | -- | μA | |||

|

Color Rendering Index |

IF=30mA | CRI | -- | -- | 80 | -- | Ra | |||

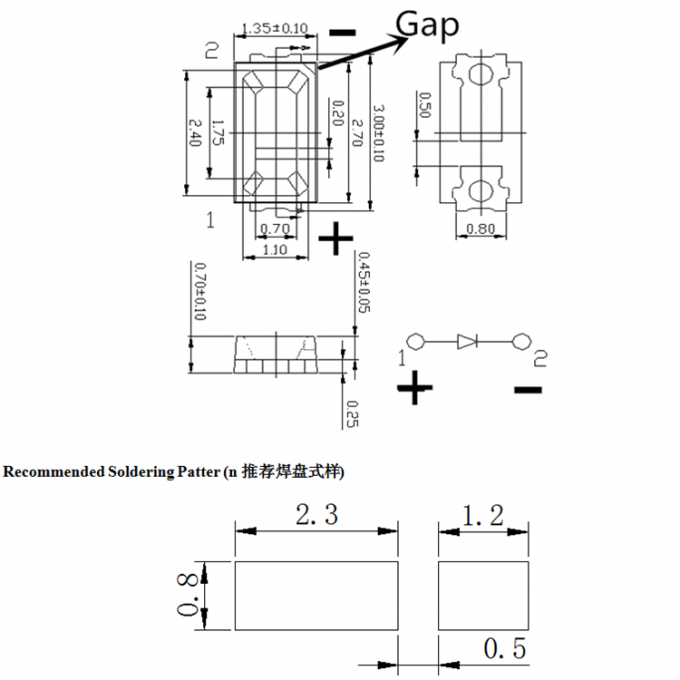

Reel Dimensions:

Carrier Tape Dimensions:

Loaded quantity 4000 PCS Per reel.

Please read the following notes before using the product:

1. Over-current-proof

Customer must apply resistors for protection, otherwise slight voltage shift will cause big current change (Burn out will happen).

2. Storage

2.1 Do not open moisture proof bag before the products are ready to use.

2.2 Before opening the package, the LEDs should be kept at 30℃ or less and 90%RH or less.

2.3 The LEDs should be used within a year.

2.4 After opening the package, the LEDs should be kept at 30℃ or less and 70%RH or less.

2.5 The LEDs should be used within 168 hours (7 days) after opening the package.

2.6 If the moisture adsorbent material (silica gel) has fabled away or the LEDs have exceeded the storage time, baking treatment should be performed using the following conditions. Baking treatment: 60±5℃ for 24 hours.

3. Soldering Condition

3.1 Pb-free solder temperature profile.

3.2 Reflow soldering should not be done more than two times.

3.3 When soldering, do not put stress on the LEDs during heating.

3.4 After soldering, do not warp the circuit board.

4. Soldering Iron

Each terminal is to go to the tip of soldering iron temperature less than 260℃ for 5 seconds within once in less than the soldering iron capacity 25W. Leave two seconds and more intervals, and do soldering of each terminal. Be careful because the damage of the product is often started at the time of the hand solder.

5. Repairing

Repair should not be done after the LEDs have been soldered. When repairing is unavoidable, a double-head soldering iron should be used (as below figure). It should be confirmed beforehand whether the characteristics of the LEDs will or will not be damaged by repairing.

INQUIRY

CATEGORIES

CONTACT US

Contact:Vicky

WhatsApp/Wechat:86-13410359515

E-mail:info@smdledlamp.com

Add:5B13-1, Futian Market Building, Fuhua Road, Futian District, Shenzhen